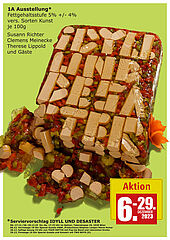

Kommen Sie nur, wenn Sie was kaufen wollen

Niclas Heider, Atelier III

REDE ZUM BILD

ERSTER AKT

Monolog vor der Tür. Zitat zum Beispiel. „Irgendwann begreift man, dass das gesamte

Leben eine Unternehmung mit unerfreulichem Ausgang ist, und beginnt hektisch

Erlebnislücken zu füllen. Im Alter vertraut nur der Idiot den Gesetzen, die er selber

aufgestellt hat.“ Sibylle Berg, Wunderbare Jahre. Als wir noch die Welt bereisten.)

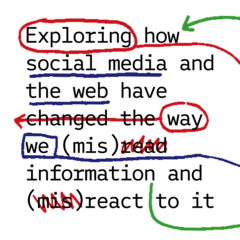

[VORANGESTELLT: Zitat zum Beispiel: „Ich mache keine Fehler“ (Wolfgang Herrndorf im

Forum Die höflichen Paparazzi)]

[VORANGESTELLT: Zitat zum Beispiel: „Don’t cry - work“ (Rainald Goetz, Irre)]

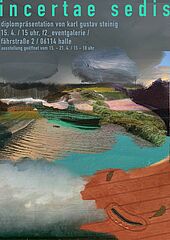

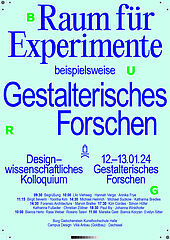

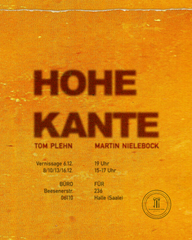

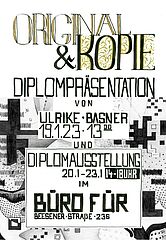

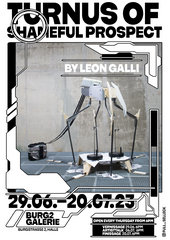

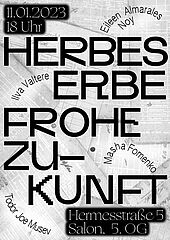

[VORANGESTELLT: ÜBERLEGUNGEN FÜR EINEN MÖGLICHEN AUSSTELLUNGSTITEL.

Auflistung: bisher keine. Siehe Liste. Siehe Plakat.]

ZWEITER AKT

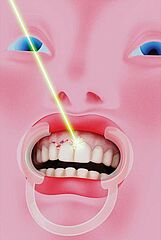

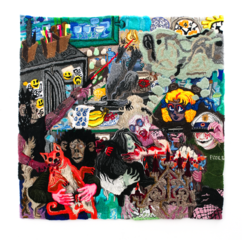

Hier zu sehen, ist eine Ansammlung von Individuen. Sieben auf einem Strich.

Es sind Bekannte, Unbekannte, Schablonen und Ideale. Manche existieren - nicht mehr

– ,manche haben nie existiert. Bei manchen hoffe ich, dass sie noch lange mit mir

existieren.

Eine auf den ersten Blick nicht homogene Masse. Variabel und eigenständig. Eine Gruppe

oder nicht? Kennt man sich? Mag sich wer? Hasst sich jemand?

Eine Idee eint sie doch, sie sind Ausgangspunkt und Startrampe für meine

Verbildlichungen. Auslöser von Irritationen und Befragungen meiner selbst und meiner

eigenen komischen Welten zwischen Instagram und Theatersaal zwischen Atelier und

Technoclub, zwischen Halle und Leipzig, zwischen Kino und Kissen.

Ich zeige hier Erinnerungen an Gehörtes (hauptsächlich Trash und Pop), Gelesens

(Herrndorf und Berg sollen bitte diesen komischen Planeten regieren!) und Gesehenes

(Bilder meiner großen Lieben, die zu viele sind, um sie hier zu nennen.)

Zunächst sei aber gesetzt: Gesehenes gleich Erinnerungen + malerische Transformation =

Bild.

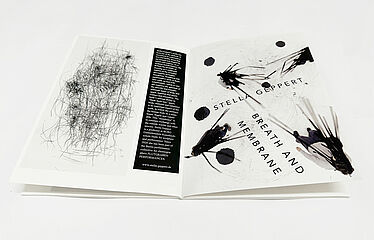

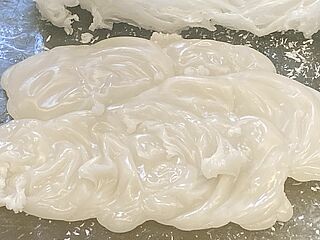

Meine Arbeiten verstecken sich hinter einem Schleier. Feiern Hochzeit oder sind in Trauer.

Mir haben sie es nicht verraten.

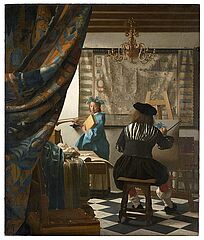

Früher waren es Monster. Was ich jetzt sehe sind Figuren auf einer Bühne. In schnellen

Pinselstrichen verbalisieren sie sich und stoßen sich ins Rampenlicht. Farbe gibt ihnen

Form. Licht und Schatten beglücken sie mit Tiefe.

Beim Schlussapplaus dürfen aber alle nach vorn. Verbeugung. Klatsch Klatsch. Abgang.

Der Dunst öffnet den Blick auf kontrollierte Feinheiten und verschrobene Ideen, die

zeitweise vordergründig aber hauptsächlich hintergründig in meinen Arbeiten lauern. In

der Konstellation trifft sich das Einzelne zum Ganzen.

Ein Dunst der alles vernichtend zusammenschlägt und triumphierend durchexerziert. Die

Bilder sind da. Hängen gut.

Im Nebel befrage ich meine eigene Unentschlossenheit, der ich es anmaße malerische

Entscheidungen zu treffen. Farbe auf ein Maltuch setzen. Loslegen. Die eigene Scheiße

machen (Ich glaube ein Zitat von Prof. Tobias).

Den Pinsel in die Hand nehmen, wenn Worte die besseren Lösungen gewesen wären.

Denke ich.

Ich lege mich trotzdem fest und verbanne den vernichtenden Konjunktiv. Malerei ist

Entscheidung, hat man mir gesagt. Ich glaube, dass es stimmt. Am Ende steht man dann

doch vor diesem weißen Rechteck und denkt an die Welt vor der Tür. Bilder fallen

langsam.

Kommen Sie nur, kommen Sie nur. Kaufen Sie!

Aber ich verliere mich.

The Oscar goes to… Nein. Ich lehne dankend ab. Nun also.