BAKER’S BUTCHERY

from industrial bread remains to mealworm protein

The concept Baker’s Butchery deals with the integration of a mealworm

farm into a bakery, in which the overproduced bakery products get converted

into protein. The integration leads to an efficient use of resources, due to

multiple uses of infrastructure. The concept shows possibilities and advantages

of a future in which insects are established as foodstuffs. It should help to

question the existing food culture and production, which is a determining

factor for global warming and the waste of resources. The Baker Chips are the

communication medium and a possibility to approach insect consumption.

All calculations are based on an existing bakery taken as an example.

The Baker Chips are the prototype of a new product, that allows consumers to get used to the taste and consumption of mealworms. At the same time, it shows another possibility to convert overproduced bread into a new sustainable product. The chips contain 85% wheat bread remains, 5% mealworm flour and 10% beetroot. The beetroot is responsible for the red colour but more importantly for the right moisture ratio to make a processable dough.

Insect benefits

It is widely accepted that by 2050 the world will host 9 billion people. To

accommodate this number, current food production will need to almost double.

Land is scarce and about 15% of all greenhouse gas emissions from human

activity are attributed to livestock production. We need to find new ways of

growing food.

As shown in the graphs, mealworms are much more efficient in the conversion of

food into protein, as well as in the use of land.

Due to their natural tendency to cluster and short reproductive cycles,

mealworms are very suitable for mass animal farming. The nutritional profile

reveals that mealworms have a significantly higher nutritional value than beef

and chicken.

Nutrition

Several tests from the Laboratory of Entomology at the University of Wageningen,

the Netherlands, have shown that bread is usable as a part of mealworm

(Tenebrio molitor) nutrition. By-products from beer-production also showed good

results in the test, due to their high protein content.

A prototype mealworm farm in France achieves good food conversion ratios with

26% protein, their diet based on 50% wheat bran, which could be a good value

protein additive. The intended organic by-product based diet has an equally

high content of 26% protein.

Rearing conditions

Mealworms are reared at a constant temperature of 28˚C. Due to the relatively

simple and short reproductive cycle, a high degree of automated production is

possible. The automation process is based on stackable containers. With a stack

height of 3.5m, an estimated production size between 4030 – 6300m² would be

required for the example bakery.

Waste heat

A drawback of mealworm breeding is a high heating energy consumption. However,

the mealworm farm benefits from using the heating infrastructure and heat

recovery of the bakery. The bakery generates an enormous amount of waste heat,

which could sufficiently supply the farm, at least in warmer months of the

year.

Hygiene

The bakery uses a large number of standard bakery

boxes for their delivery, which are washed after delivery by an industrial

tunnel washing system. Since it can cover a throughput of up to 2000 boxes an

hour, it can also be used for cleaning the mealworm containers, which are

similar to the bakery boxes.

Transport / sale

Transport routes are already used to return the remaining bread to the production site. The transport and sales structure can also be used for the new raw material mealworm and emerging protein-containing products. The bakery of the future will also be a protein supplier, similar to a butcher.

Calculations for example bakery (based on a real bakery)

Bread remains:

monthly: 6% of total bakery production > 33 tonnes

3% of the bread remains already reused within the bakery = 1 tonne

Approx. 32 tonnes of bread remain as the nutrient basis for the production of mealworms.

Monthly:

| Beer Yeast | 10% | 10.6 tonnes | 48% protein |

| Spent Grain | 40% | 42.4 tonnes | 25% protein |

| Bread Remains | 30% | 32.0 tonnes | 13% protein |

| Wheat Bran | 20% | 21.2 tonnes | 34% protein |

| 100% | 106.3 tonnes | 26% protein |

3,5 tonnes nutrition / day > 1 tonne mealworms / day

The food conversion ratio (FCR) for mealworms lies between 2.5 and 3.5. Due to the use of by-products the highest FCR value has been taken for calculation.

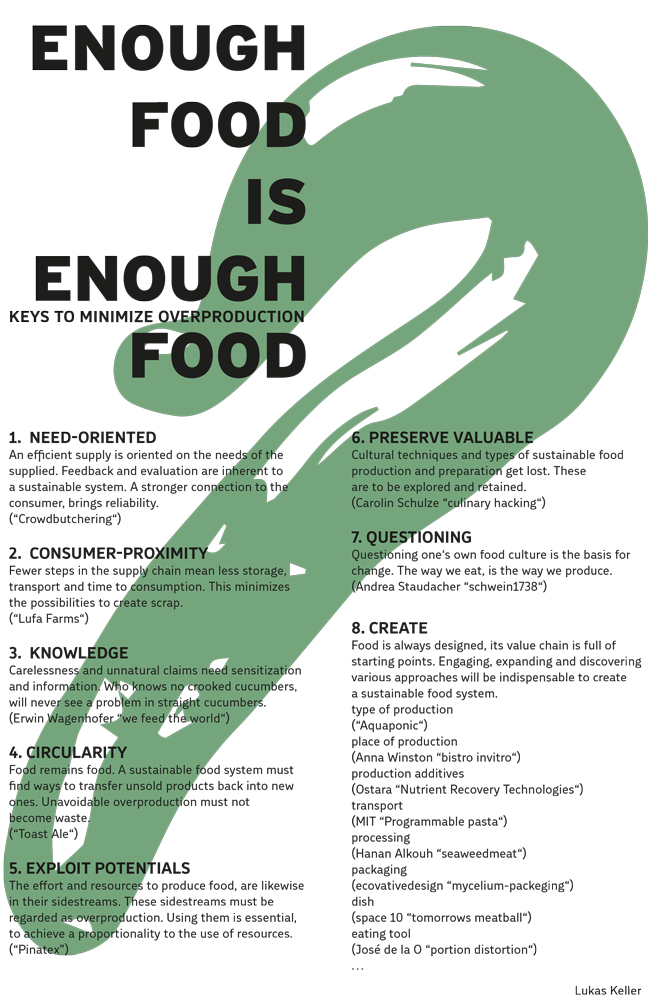

Manifest by Lukas Keller

| student: | Lukas Keller |

| project: | REUSE |

| year: | 2018 |