GARNET SAND 3+

tiles and vessels

How can we use the large amount of shapeless waste sands, containing different particles of the cutting materials, which come from a normal water jet cutting factory? Through experiments with porcelain, glass and the simulation of the sinking process I found out that those waste sands could be suitable in the porcelain industry. It can be added to the traditional porcelain-making process to make everyday vessels. Another characteristic of this mixture is the anti-slip property, which is very well suited as an additive in tiles for floors in sanitary areas. On walls, the metallic property can be used as a magnetic pinboard.

Every 3–4 months 4 tonnes of garnet sand are disposed per machine.

Chemical components of the waste sands:

| Al2O3 | 20% |

| FeO | 30% |

| SiO2 | 36% |

| MnO | 1% |

| CaO | 2% |

| MgO | 6% |

Characteristics:

• red when dry – black when fired

• edged

• sharp angle

• slightly magnetic

• translucent

• contains no free chemicals

• hardness: Mohs 6–8

• melting point: 1250 °C

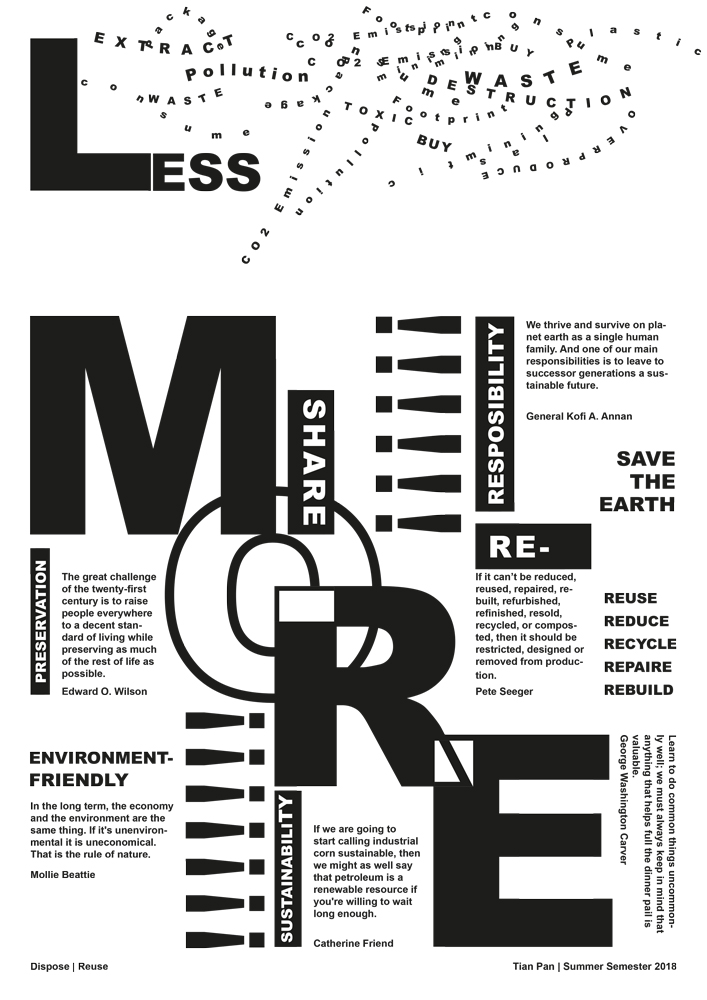

Manifest by Tian Pan

| student: | Tian Pan |

| project: | REUSE |

| year: | 2018 |