PRECIOUS PARTICLE

Exploration, experimentation, creation and production of sustainable particle foams

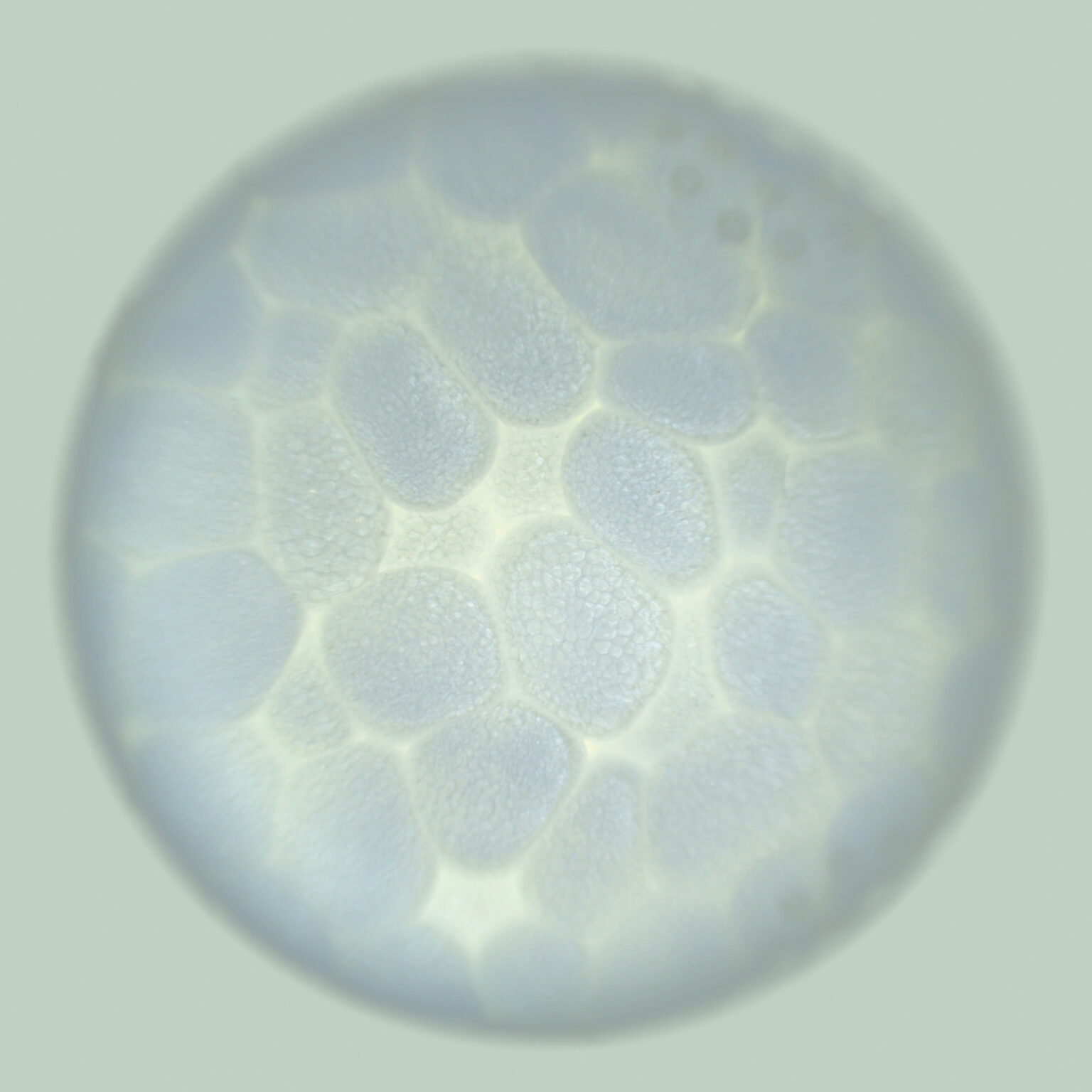

Particle foams are ultra-lightweight, thermally insulating, highly recyclable, versatilely mouldable – and yet often unpopular because they are associated with short-lived packaging made of Styrofoam® or questionable insulation. However, the world of particle foams is much bigger:

On the one hand, besides expanded polystyrene, or EPS for short, a variety of materials can be processed in the same way, such as EPP, EPLA, ETPU or even popcorn, which allow for unexpected applications. On the other hand, there are new processes: RF technology uses electromagnetic waves instead of steam, which not only saves energy, but also allows EPS to have 100 per cent recycled content.

In the project, we learned about this industrial technology and the relevant materials. We experimented with particle foaming on our own in the workshop – not only at the CNC cutter, but also in the extra-large pressure cooker.

We investigated the potentials and problems of particle foam in everyday life and developed ideas for useful and more sustainable particle foam products in several sprints.

We selected the best ideas and foamed them in specially made tools with RF technology at the partners Fraunhofer ICT and Kurtz Ersa.

The students opened up new contexts and experimented with alternative processes and materials. In alternating teams, they developed forward-looking particle foam products – which meet the demand for responsible use of resources, energy, consumption and production and whet the appetite for tomorrow.

| supported by: | Prof. Mareike Gast Karl Schikora Andi Wagner |

| year: | 2023 |

| level: | 2nd year BA |